Specification

| Bore and stroke | 105 x 120 mm |

| Displacement | 3.12 L |

| Cylinder Number | 3 |

| Compression ratio | 15.5:1 |

| Fuel System | Mechanical Pump |

| Aspiration | NA/T |

| Emission Standard | IMO Tier II |

| MODEL | RATING | HP | KW | RPM | g/kwh | I/h | CERTIFICATION |

| D226B-3C1 | P1 | 48 | 35 | 1800 | CCS | ||

| TD226B-3C1 | P1 | 68 | 50 | 1800 |

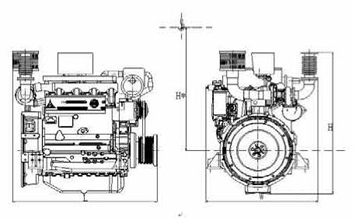

| LENGTH | WIDTH | HEIGHT | NET WEIGHT |

| 890 | 550 | 1060 | 460 |

| Bore and stroke | 105 x 120 mm |

| Displacement | 3.12 L |

| Cylinder Number | 3 |

| Compression ratio | 15.5:1 |

| Fuel System | Mechanical Pump |

| Aspiration | NA/T |

| Emission Standard | IMO Tier II |

Engine and Block

– Cast iron gantry type structure block

– One-piece forged crankshaft

– Separate cast iron cylinder heads and wet liners

– Aluminum alloy pistons with gallery oil cooling

Cooling System

– Fresh/raw water heat exchanger with integrated thermostatic valves

– Cast-iron centrifugal fresh water pump, mechanically driven by belt

– Self-priming raw water pump, mechanically driven

Lubrication system

– Spin-on full-flow lube oil filter

Fuel System

– In-line fuel injection pump

– Duplex fine filter and large capacity pre-filter for better efficiency

Intake Air and Exhaust System

– Insulated exhaust manifold and exhaust expansion joint

Electrical System

– 24V electric starter motors and battery charging alternator

– Standard sensor connector

Flywheel and housing

– SAE3 Flywheel housing and 11.5″ flywheel

Certification

– CCS

– Different harness length of remote monitor

– Free end PTO

– Equipment and factory trial according to Major Classification Societies rules