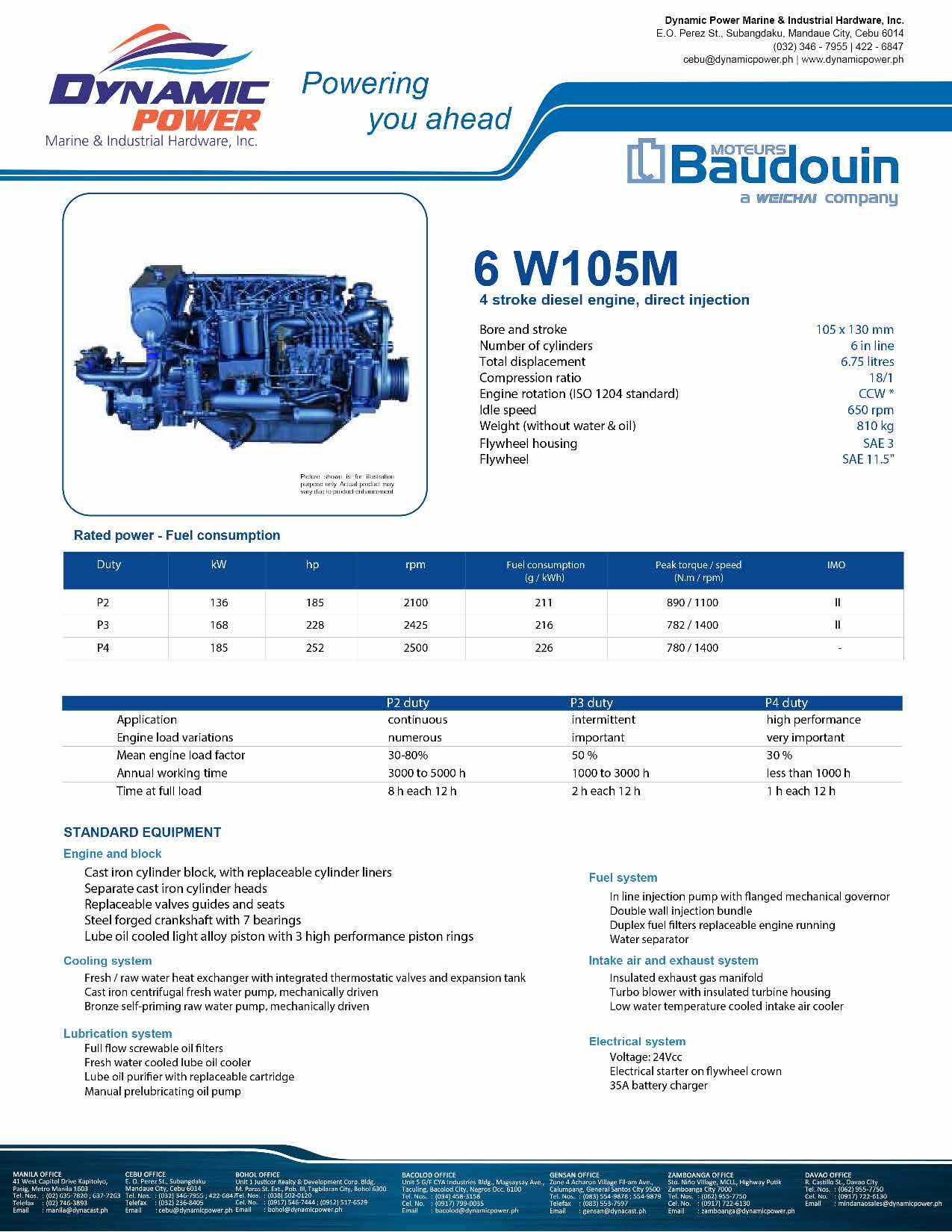

Features

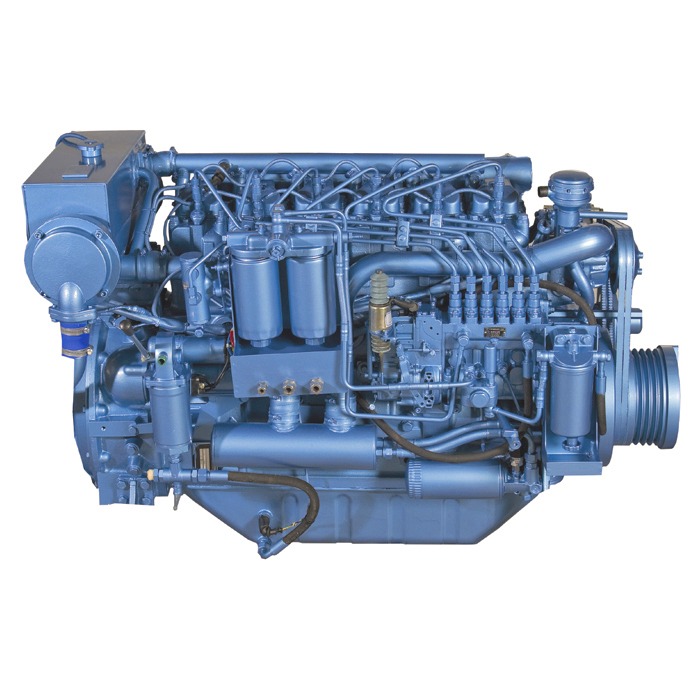

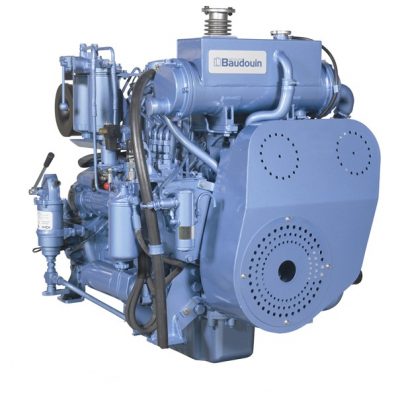

Engine Design – This engine is design for continuous duty operation. It has six cylinders that enhances the performance.

Engine and block –

- Cast iron cylinder block with replaceable cylinder liners

- cast iron cylinder heads is separated,

- the valves guides and seats are replaceable.

- Steel forged crankshaft contains 7 beatings,

- light alloy piston with 3 high performance piston rings.

Fuel System –

- In-line injection pump with flanged mechanical power

- duplex fuel filter replaceable while engine is running

- water separator.

Lubrication System –

- full flow screwable oil filter

- fresh water cooled lube oil cooler

- Lube oil purifier with replaceable cartridge

- manual prelubricating oil pump.

Air Intake System –

- It has Insulated Exhausted gas manifold,

- Turbo blower with insulated turbine housing dddd

- low water temperature cooled intake air cooler.

Electrical System –

- Voltage that contains twenty four with insulated,

- Electrical starter on flywheel crown

- 35A battery charger.

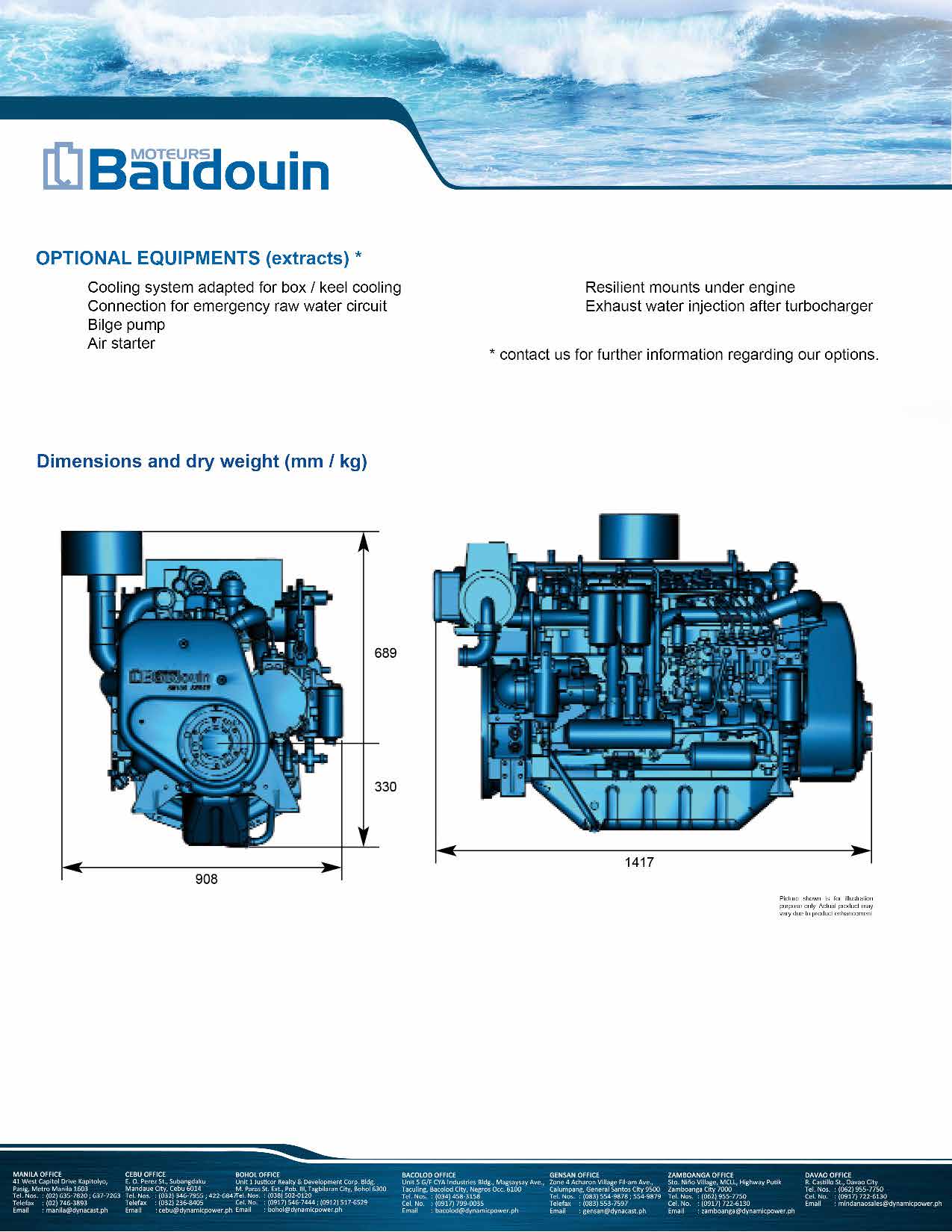

Optional Equipment

- Cooling system adapted for box / keel cooling

- Connection for emergency raw water circuit

- Bilge pump

- Air starter

- Resilient mounts under engine

- Exhaust water injection after turbochargerEngine Design – This engine is design for continuous duty operation. It has six cylinders that enhances the performance.Engine and block –

- Cast iron cylinder block with replaceable cylinder liners

- cast iron cylinder heads is separated,

- the valves guides and seats are replaceable.

- Steel forged crankshaft contains 7 beatings,

- light alloy piston with 3 high performance piston rings.

Fuel System –

- In-line injection pump with flanged mechanical power

- duplex fuel filter replaceable while engine is running

- water separator.

Lubrication System –

- full flow screwable oil filter

- fresh water cooled lube oil cooler

- Lube oil purifier with replaceable cartridge

- manual prelubricating oil pump.

Air Intake System –

- It has Insulated Exhausted gas manifold,

- Turbo blower with insulated turbine housing dddd

- low water temperature cooled intake air cooler.

Electrical System –

- Voltage that contains twenty four with insulated,

- Electrical starter on flywheel crown

- 35A battery charger.

Optional Equipment

- Cooling system adapted for box / keel cooling

- Connection for emergency raw water circuit

- Bilge pump

- Air starter

- Resilient mounts under engine

- Exhaust water injection after turbocharger