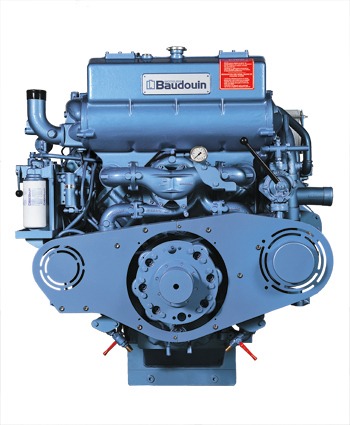

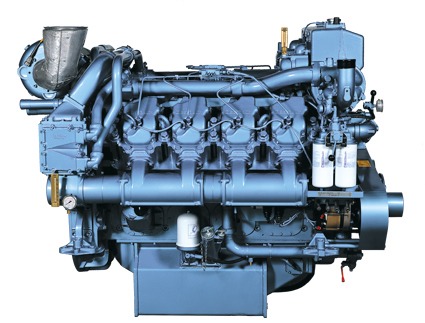

Features

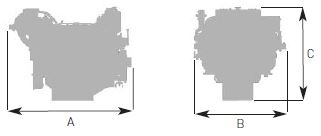

Engine Design – This engine is design for continuous duty operation. It has eight cylinders that enhance the performance.

Engine and block –

- Cast iron cylinder block

- One inspection door per cylinder for access to conrod cap

- Cast iron cylinder liners, wet type

- Separate cast iron cylinder heads equipped with 4 valves

- Replaceable valves guides and seats.

- 8 cylinders heade tightening bolts

- Hardened steel forged crankshaft with induction hardened journals, crankpin and radius

- Camshaf with polynomial cams profile

- Distribution with tempered, hardened and grinded helicodal gears

- Chromium- Molibdenum steel conrods

- Lube oil cooled light alloy pistons with high performance piston rings

Fuel System –

- In-line injection pump with flanged mechanical power

- Double wall injection bundle with leakage collector

- duplex fuel filter replaceable while engine is running.

Lubrication System –

- full flow screwable oil filter

- fresh water cooled lube oil cooler

- Lube oil purifier with replaceable cartridge.

Air Intake System –

- Fresh water cooled trubo blower

- double flow raw water cooled intake air cooler.

Electrical System –

- Voltage that contains twenty four with insulated

- Electrical starter on flywheel crown

- 175A battery charger.

Cooling system –

- Fresh / raw water heat exchanger with integrated thermostatic valves and expansion tank

- Cast iron centrifugal fresh water pump, mechanically driven

- Bronze self- priming raw water pump, mechanically driven.

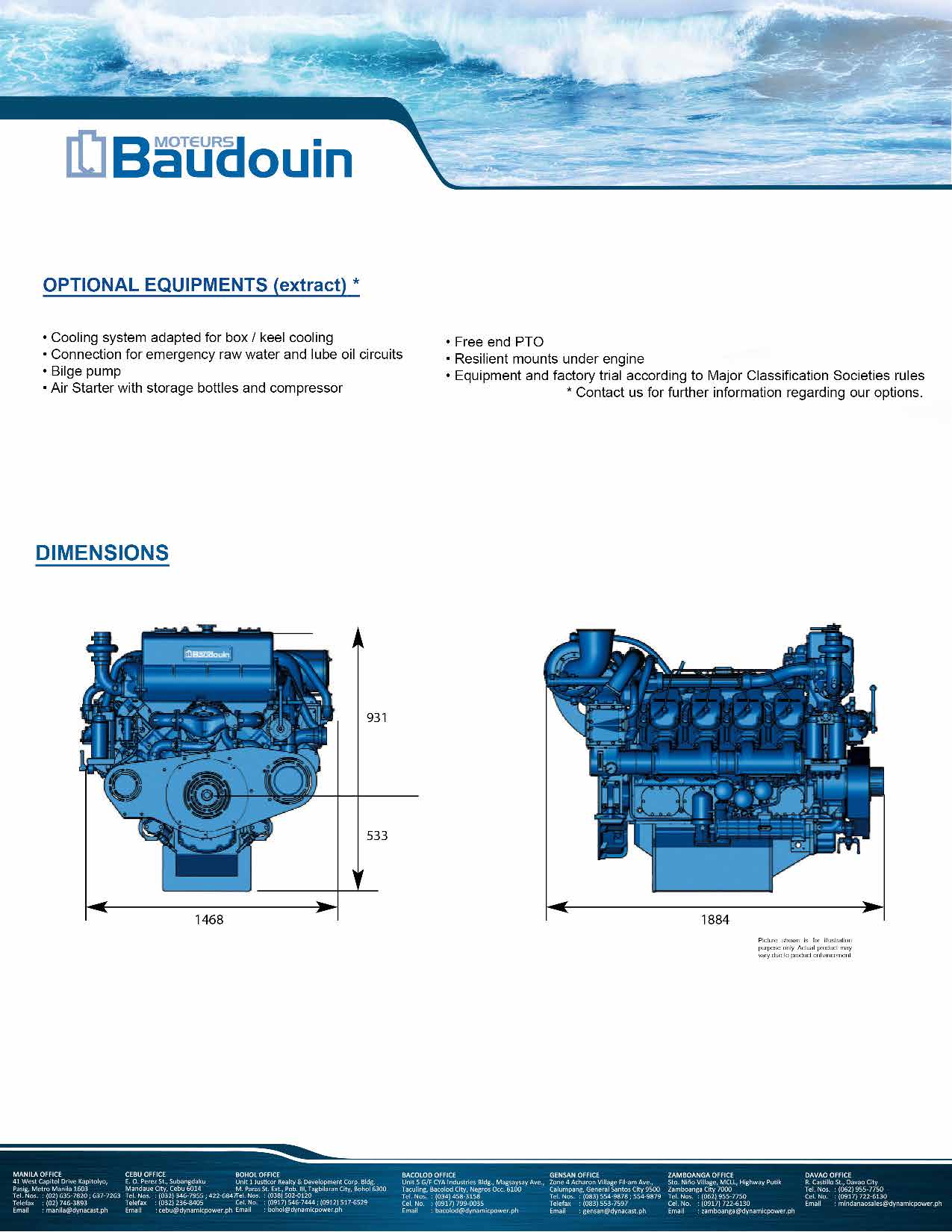

Optional Equipment’s

- Cooling system adapted for box / keel cooling

- Connection for emergency raw water and lube oil circuits

- Bilge pump

- Air Starter with storage bottles and compressor

- Free end PTO

- Resilient mounts under engine

- Equipment and factory trial according to Major Classification Societies rules